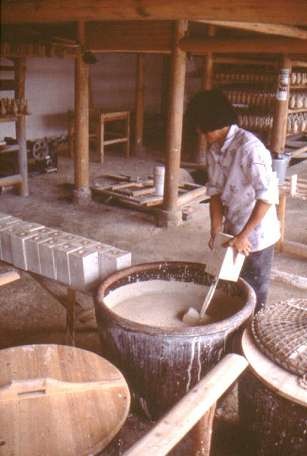

Slip casting vases at at a small pottery workshop along the road towards Sanbaopeng just outside of Jingdezhen, Jiangxi province, 1992.

Photo © Jan-Erik Nilsson 1992

The process of making pottery by pouring liquid clay (slip) into absorbing plaster molds. The slip is left in the mold for a while a layer of slip has solidified against the interior wall of the mold. The excess still-liquid clay is then poured out, and the layer of slip is left to dry inside the mold. Once solidified, the leather-hard item is removed from the mold, trimmed neatly, and allowed to dry. This process easily produces hollow, round wares, like pots and vases, with a thin body of even thickness. The same process can be used for handles, spouts, and other details.

If visible at all, the parting mark left by the mold on these wares is vertical, whereas all antique porcelain vessels were molded in horizontal sections, if at all. The practice of using plaster of Paris molds began in 19491), whereas earlier pottery molds absorbed water more slowly and generally produced objects with thicker walls.

1) Information repeatedly given during interviews in Jingdezhen in 1992

A